WIESNL

WIESNL Projects

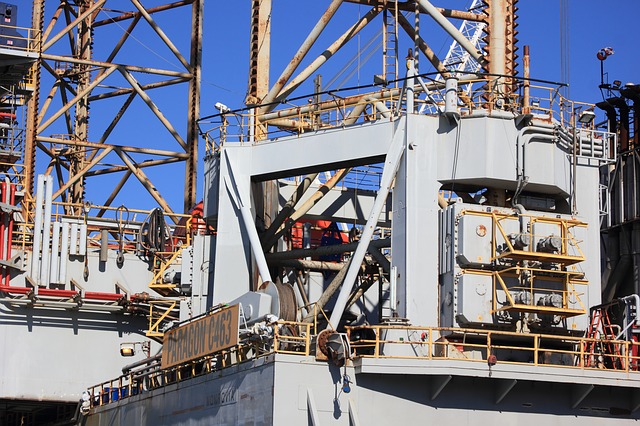

SPDC EA Sea Eagle Turnaround

We are currently part of the team involved in the turnaround maintenance of Shell Petroleum Development Company’s Sea eagle FPSO. We carried out integral corrosion assessment and are currently making repairs to affected areas. We have also developed a comprehensive corrosion management plan to effectively secure the facility against future occurrence. We are also involved in the provision of AUT inspection services for the EA Riser repairs and maintenance. This involves both probing and interpreta?on of test results.

Bonga North West Phase II Project (SNEPCO)

In early 2014, WIES actively participated in the Subsea hardware fabrication of wellhead production jumpers at Aveon Offshore, Port Harcourt. As part of the project, we carried out third party AUT inspection of welded girth joints using Tandem technique. This involved inspecting all the joints and confirming their integrity before deployment subsea.

Prior to this, WIES had been extensively involved in man power supply during the fabrica?on of the Bonga North West Flow line duration at Saipem yard Port Harcourt. Providing highly experienced QA/QC Engineers and inspectors to monitor various parts of the project on behalf of SNEPCO. Our team of inspectors were involved in both onshore and offshore activities. We advised on proper anti corrosion techniques to be implemented and ensured proper coating was done on the materials according to industry standard. We also fabricated the Pull-in skid that was used in the Bonga North West II project

Bonga Main

We were involved in the pre commissioning and commissioning of Top side modules of Bonga Main FPSO. We also under took the recalibration and certification of all high pressure valves onboard the FPSO. We also provided assistance in the area of corrosion control and repairs during the project.

Home